|

ELIMINATE DOWNTIME AND BOOST PRODUCTION END TO END PRODUCTION MONITORING ACHIEVED SIMPLY AND AFFORDABLY Stop reacting and start predicting Let’s face it, condition monitoring of assets and equipment can be expensive and inefficient. If you never know what’s around the corner, it’s hard to plan for it... If you have experienced counting the cost of downtime or struggled with unpredictable, ‘reactive’ maintenance, you already know how damaging this is to your business. Now, more than ever, it is easy to gain control of your operations by combining the hardware, software, security and services you need to manage your equipment more efficiently. “We have tried this before and it has never worked” Production tracking. Many companies have tackled this challenge before and have ended up stalled, frustrated and further from a solution than the day they started. Why? The reasons are varied and understandable:

With standard charting and KPI packages, you cannot connect directly with your equipment – you only have access to a database. It's frustrating to learn that actionable information is buried in a complex software program. How can you access this data? How will the system be maintained? Often, the answer requires additional expertise from outside your company and the proposition becomes more complex and expensive than you bargained for. But, what if it doesn't have to be that way..

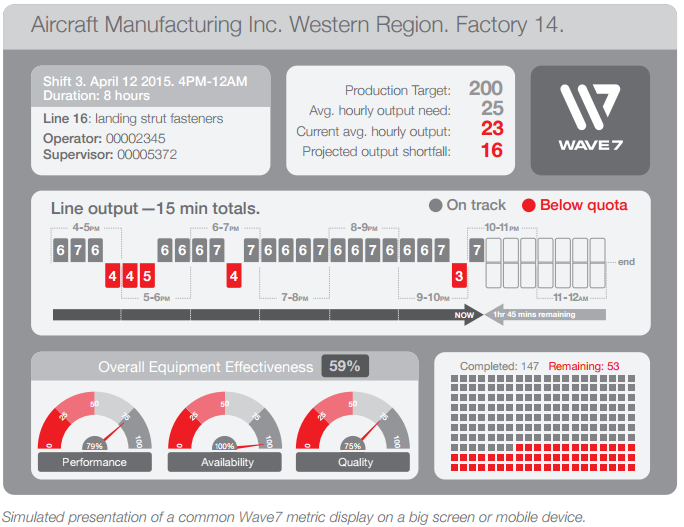

Take control of your company's production assets today! GoldStar Automation has vetted and interviewed several suppliers of production tracking solutions. Each solution had merit and did a very good job of “grabbing” data from plant assets. Only one company leap frogged the competition to offer the one thing that is missing from the rest of the pack. Wave7 is the first company to take advantage of the IIoT (Industrial Internet of Things) to deliver an end to end information solution. Their five-point approach is unlike any other:

Wave7 provides an immediate improvement to your bottom line. Start with one, or several assets and realize immediate returns. Each connection (Droplet) is a complete Wave7 system that is modular and achieves scalability from one to hundreds of assets. OEMs that rely on spare parts and service as their main post-delivery revenue now have a powerful value proposition- deliver traceability on each machine and offer as a service to the end customer. The solution to gaining control of your company’s most important metric, it’s efficiency, is closer than you thought. Contact the automation experts at GoldStar Automation to help you get started.

1 Comment

|

Archives

October 2017

Categories |

RSS Feed

RSS Feed